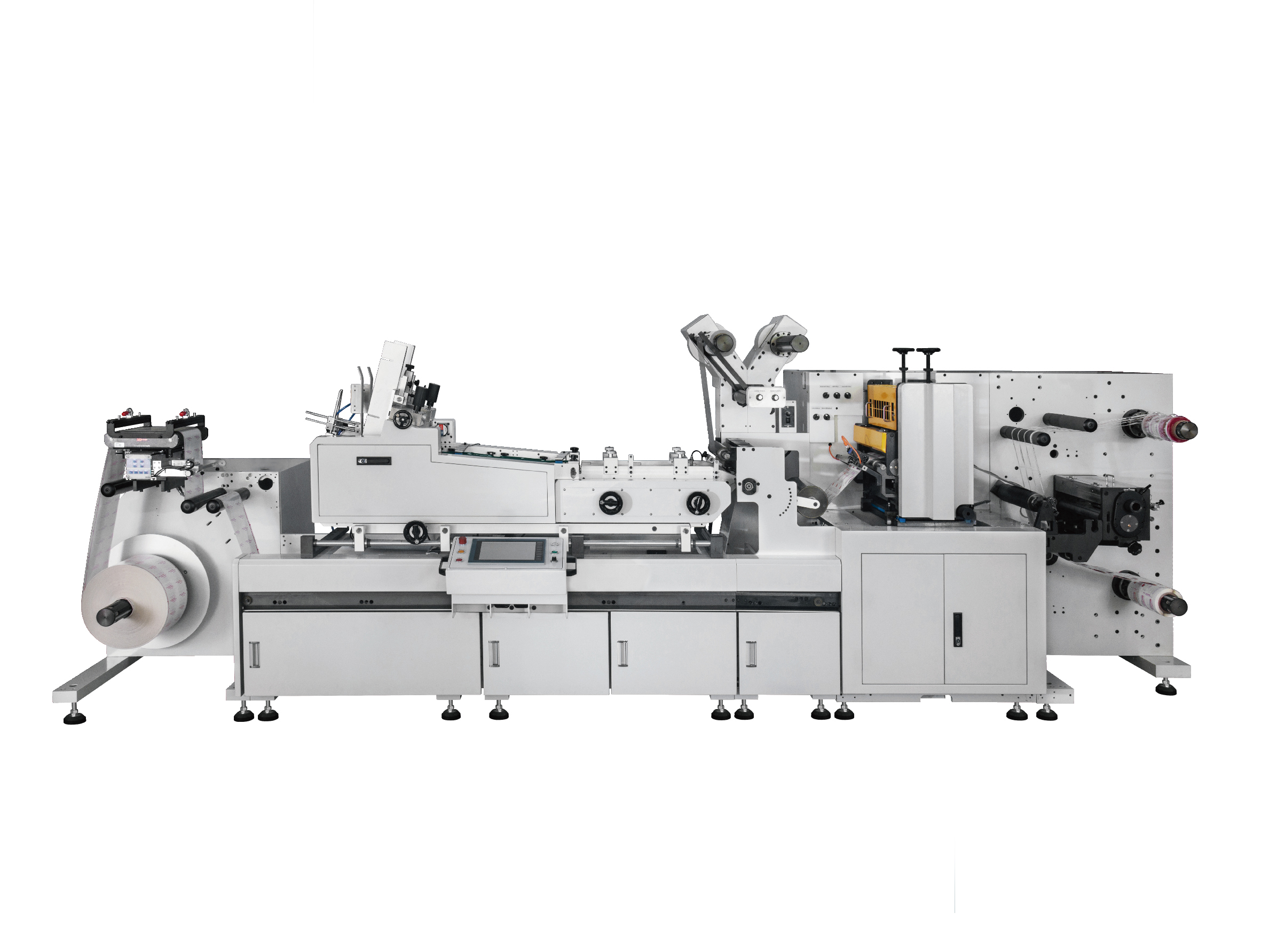

Booklet(ECL) Label Converting System

The Brotech BF has been developed for the converting system roll to roll booklet(ECL) label converting market sector. It is capable of complete converting and finishing of booklet(ECL) labels of 4 to 24 pages and 50-250mm in length. Brotech’s patented feeder is designed to ensure stable and smooth registered feeding, quickly set up time and easy to operation. Alignment is controlled with 2 belts for transfer and equipped with accurate side registration, suitable for the folding of a broad variety of labels.

1.TECHNICAL SPECIFICATIONS

| MODEL | BF 330 | BF 420 |

| Max web width | 340mm | 430mm |

| Max unwind diameter | 700mm | 700mm |

| Max rewind diameter | 600mm | 600mm |

| Max die cutting width | 330mm | 420mm |

| Max running speed | 12000 pieces/hour | 12000 pieces/hour |

| Die cutting registration tolerance | ±0.15mm | ±0.15mm |

| Air supply | 8bar | 8bar |

| Rated voltage | 3PH+N+PE | 3PH+N+PE |

| Size (length × width × height) | 5.1×2.8×1.8m | 5.1×2.9×1.8m |

| Machine weight | 2.5T | 3T |

2.SUBSTRATES

Standard material thickness is 35µm~250µm of film / paper / adhesive material / light carton board. Other special materials need to be tested.

3.FUNCTIONING UNITS

Feeder:

Motorized modular design feeding knife with blocks for smooth and stable feeding.

Alignment:

2 belts transfer with accurate side-position registration for folding a wide variety of labels.

Lamination:

Magnetic particle clutch to control smooth unwind/rewind, max lamination roll 350mm.

Die Cutting:

Full-rotary for use with magnetic or solid cylinders.

4.APPLICATIONS

Electronics, cosmetics, packaging, pharmaceutical, toys, logistics, garments, security, industrial / chemicals, etc.

5.FEATURES & ADVANTAGES

Brotech’s patented feeder is equipped with servo motor to ensure smooth delivery and accurate registration. As well Brotech design offers a modular designed feeding knife and blocks for smooth and stable feeding with perfect registration. A dual belt transfer system provides accurate side-position registration for folding a vast variety of labels. The fully servo driven die cutting station equipped with magnetic or solid cylinders for easy and highly efficient use and job change over.